Hi Gang..

As most of you know, we had a great time at Amelia Island on March 14th at the Concours d’Elegance. Bill Warner and Tom Cotter put on a masterful show – worthy of all recognition and respect for all of the cars and dignitaries that participate and enjoy the Concours – and the events that preceed it prior to that Sunday. Kudos to the Amelia Island Concours staff for making the show the fabulous event it is each year.

With that said, I thought it was about time that I show you in detail the rest of the cars that appeared at Amelia Island. Prior to the event, we covered Dudley Cunningham’s Meteor SR1 and Phil Fleming’s Devin. So without adieu, let’s get to it, and get to know Steve Steers’ magnificent Victress S1A.

Back in the 1950’s, Steve’s father built specials to drive and race. Two of his favorite cars were a Glasspar bodied sportscar he built – and his Victress S1A as well. Steve carried this memory with him for many years, but it wasn’t until after the year 2000 that he decided to act on it. Even then, it wasn’t easy finding any type of special body from the 1950’s. You might think it’s pretty hard now, but at that time, Hemmings, local ads, and word of mouth were about it. Very little was available on the internet concerning these cars.

Steve checked out many cars he found over the years, but was looking for a special car that he could complete to his own design and style. It was after several years that he found a Victress S1A with Mameco frame that was nearly unmolested and ready to be built. Of course it wasn’t close to where he lived. Texas was a long way from Chicago, but the body he found had not been abused and had been stored inside for many years. And with that start, Steve was off and running on a multi-year project. To tell the story best, let me step aside and have Steve share the story himself:

From the Desk of Steve Steers…

It was 1958. I was 15, with six months to go before qualifying for a drivers license. My Dad, John Steers, was building a car out in our two car garage in Palo Alto, CA. He had built four cars before, but this one was different. Gorgeous, with swoopy lines, a Ferrari-like grille opening, long, streamlined back end and a light flywheeled, rumpety, solid lifter Chevy V8 under the hood. Instead of just dual exhaust, it had four pipes all the way back. A feast for my young eyes and ears, and did it GO. It was sensational. I loved it.

Pop was a talented backyard engineer/fabricator. He built boats, cars, houses, garages, hammocks, awnings, furniture, barns corrals….he always had to be building something. He built five cars. The first was a rear-engined Model A built during a 6-week vacation. When it came time to decide on a body, he didn’t want to mess with all that metal work, so made up some bulkheads, ran stringers and covered it with dope and fabric like a light airplane. He sold it to some high school kids who claimed to have built it themselves. It looked like sort of a…. half dirigible, or a turtle in head-retract mode.

The next was a 36 Ford-based sports car. He used the Ford running gear, put in a 24 stud flathead, made up a plaster mold, popped a fiberglass shell off it and voila, a little car that flat out would do 100 miles an hour. He made the body in one piece, all the edges going straight down so it would release from the mold. It looked like….”an old woman bent over,” he’d smile and say. He gave it to our friend Mike Studzinski.

The next was a tube frame Glasspar-bodied sports car with a ¾ race flathead. He ran 25-tooth Zephyr gears, a 3:54 rear end and Ford straight axles front and rear. Fully street legal, he joined the SCCA in 1956 and raced that car at Stockton, Arcata and Tracy airfields, always finishing 1st or second in class. My brothers and I loved riding to the track with him.

Each car was more and more sophisticated, faster and better looking. Chevrolet now was producing their new V8 that was light and made good power, one horsepower per cube in 1957 fuel injected form. And Plymouth the same year had torsion bar suspension under their new cars. Pop always liked the idea of torsion bars as they take the suspension load toward the center of the frame where all the X-member strength is. So his next project was a Plymouth-framed, Chevy-powered car, and his body decision went to Victress, a small fiberglass body maker in Southern California.

You could buy a Victress in two wheelbase lengths, 94” or 99”. His was the S1-A at 99″. It came from the factory with a hinged, lockable hood, hinged doors and hinged decklid, although you could order them without. Victress used either Z’d Ford frames or 2”X3” box frames manufactured by Mameco Corp. in Los Angeles. The Mameco units had two rails, a high, gusseted kickup in the rear, a center X member plus Ford crossmembers front and rear for transverse spring setups. They had front split wishbone mounts welded along the frame sides.

Pop finished his car in 1958. In final form it used a 265 Chevy V8 from a station wagon, bored to 283 CI. It had fuelie heads and pistons, Duntov 30-30 cam and 3, 2bbl Rochester carbs on an Offenhauser manifold. Unable to get his hands on a Chevy 4-speed, he made an adaptor plate, used a Jaguar Moss box and a Plymouth positraction differential. He fabricated his own coil spring setup in the rear with a watts link. It had Plymouth drum brakes with ceremetallic lining on all four wheels.

A real innovation was an airfoil mounted under the rear end behind the rear wheels. It was pivoted in back, sprung with surplus parachute shock cord and connected to a lever in the driver’s compartment. Its purpose was to slow the car and create downforce. He’d blast down the straights and when a turn came up, snap the airfoil down which he figured at 100 MPH created 300 Lbs. downforce. After the turn was negotiated, the airfoil was pulled up until the next turn. A picture of the car at Laguna Seca with my brother Tim looking on is attached. Note the airfoil. He was fond of calling it his, “reverse manure spreader.”

To a 15 year-old kid all this was pretty exciting stuff. Pop kept the car until 1961 and sold it to a family friend. I never forgot it and all my life casually looked for Victress stories and pictures in the old magazines. Then in 2004, I was between projects, had some loose coin and decided to seriously look for a Victress. For years I had saved a tiny sale ad for a Victress body shell in El Paso. I chanced a call to its owner. He said, no, it never did sell years earlier, yes he still had it and yes he’d consider selling. Hot damn!

When I got to El Paso I couldn’t believe my eyes. There, hanging in a garage was a weatherbeaten, but new Victress S1-A body shell. It was never painted, still was natural fiberglass color, still had mold release on it from some fifty years earlier and still had the factory jig clips molded in all four corners. And over in a corner was a factory Mameco frame with a crude cowl hoop, rear bulkhead and a mess of angle iron welded to it, obviously someone’s attempt to fit out the frame for the Victress. It also had a dual exhaust underneath suggesting it may have been engined at one time. The body’s hood had a round cutout for an air cleaner so I suspect the body had at least sat on that frame over an engine at some point, but the car was never finished.

So we made a deal, I rented a 20 Foot Ryder truck and two days later the whole shebang was in Chicago. The car is now a roller with independent front suspension, a four link setup and coilovers in back. Power is a 1957 Dodge Hemi KD500. Work left to do is to secure the body to the frame, build a windshield, plumb and wire it, build a dashboard, install gauges, upholster it, and probably scores of smaller jobs along the way getting it finally finished.

Thanks to: Bob McKee, Russ Olsen and Ed Brett at McKee Engineering….engineering, fabrication and machining. Skip McCabe and Al Bauschke at McCabe Auto Restorations… body work and paint. Mike, Tony and Joe Yank at Speed Performance….engine buildup and dyno. Friends Jack Bowser, Herb Lederer, Jack Heist, Jim Manz, Bill Ullrich, Derry May and Jim Robinson, Geoff Hacker, Jon Greuel…moral support and extra hands. John D. Steers, Father, racer, engineer… for inspiration and showing the way.

For further information contact:

Steve Steers, ssteers@comcast.net , (847) 295-2257

Postscript:

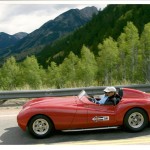

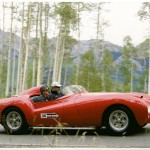

Steve finished his Victress in 2009 and drove it successfully in the Colorado Grand the same year. Some of the pictures of this event are shown below. Most recently, Steve participated in the Amelia Island Concours d’Elegance in March 2010 and pictures from this event appear below too. Steve’s car was a real crowd pleaser and is a premier example of a Victress built and restored to the best of condition.

Of special mention is that Merrill Powell, co-founder of Victress in the early 1950’s both rode in and drove Steve’s Victress as part of the Amelia weekend festivities. As they drove by, you couldn’t imagine two happier guys in the world, driving the Victress toward the beach at Amelia.

Great story Steve, and thanks for sharing!

Geoff

| Technical Specifications | |

| Body | 1954 Victress S1A |

| Designer | Hugh Jorgensen and Doc-Boyce Smith 1951-1952 |

| Body Work and Paint | Skip McCabe and Al Bauschke at McCabe Auto Restorations |

| Upholstery | Ray Morey at Restorations Unlimited |

| Frame | Mameco |

| Suspension | Modified Mameco Frame * Front: Independent front suspension (unequal length A arms and coil springs) * Rear: Four link setup and coilovers |

| Engine (make/year) | 1957 Dodge Hemi KD500 |

| Carburetion | 2 four barrel Carter WCFB |

| Displacement | 325 cubic inches |

| Horsepower (estimated) | 305 horsepower |

| Transmission (type/year) | Tremec TKO600 5 Speed, .82/1 fifth gear (manual) |

| Rear Axle / driveshaft (open/closed driveshaft) |

Ford live axle |

| Wheelbase | 99 inches |

| Track/Tread (front/rear) (distance between center line of tires) |

|

| Tire Size | Dunlop ‘L Series Racing Tires Front: 600 x 15 Rear: 650 x 15 |

| Curb Weight (estimated) | 2300 lbs |

| Top Speed (0-60) | Fast |

| Special Features | Custom wraparound racing windscreen Tilt front hood Aluminum egg crate grill 1950 Pontiac Taillights Stewart Warner Gauges Vintage Firestone Heater / defroster (for cold Chicago weather driving) Driver’s door and deck lid had to be fabricated and hinged (factory scribe lines were still on car). Passenger door and hood was factory cut and hinged |

——————————————————————–

Click on the Images Below to View Larger Pictures

——————————————————————-

- Steve at the Amelia Island Concours d’Elegance in March 2010

- Mold Separation Lines Still Visible at Rear of Car

- When Home: Restoration begins in Chicago

- Mameco Frame: Modifications begun in 1950’s but ceased before completion

- Victress S1A Body: As found in Texas

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.