Hi Gang…

We last checked in with Dave Peterson and his Byers SR100 in late 2011. Click here to review this story from 2011. Recently, Dave contacted me with an update to his story and car – an update that he was kind enough to write up and share with all of us here at Forgotten Fiberglass.

Let’s hear the what, when, where, and why straight from Dave Petersen about his Byers S100. Take it away Dave 🙂

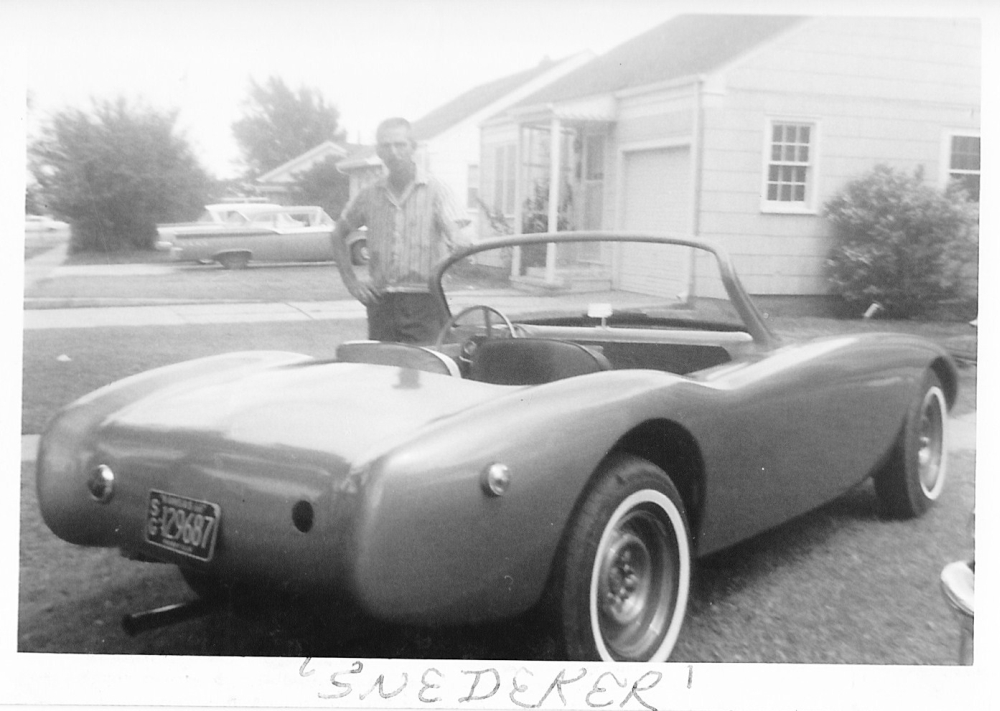

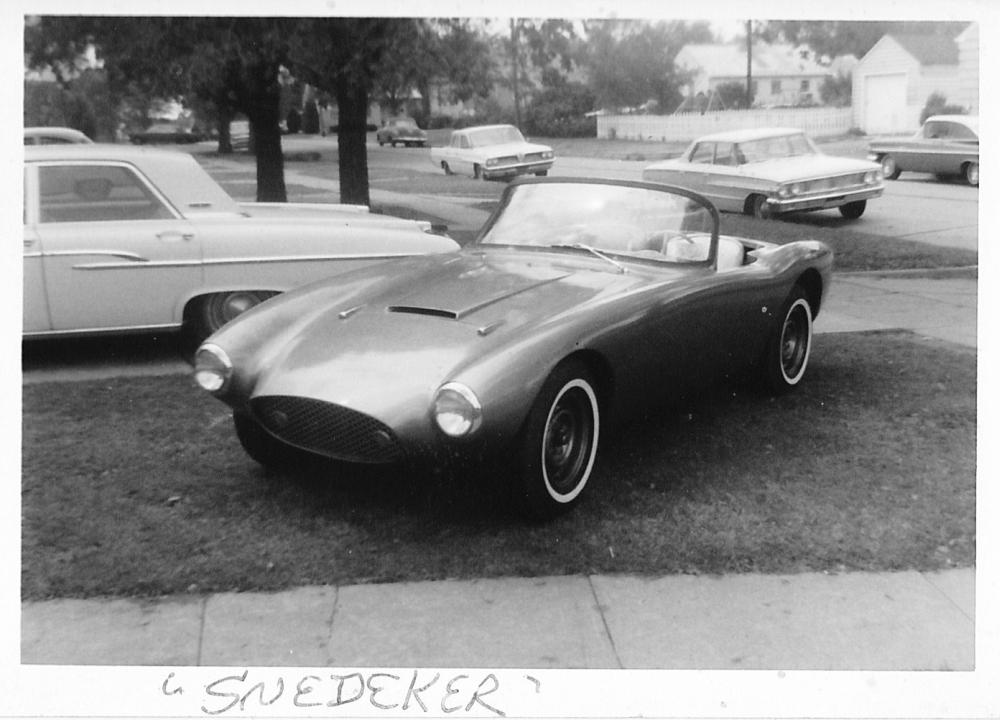

Update on the Snedeker Byers SR100

By Dave Petersen

Our story left off in 2011 (click here to review Dave’s story from 2011) when the prior owner unearthed the title to this particular Kellison-Byers SR100 almost four years after I purchased the car. That’s one star that aligned for me. When was the last time a previous owner actually sent anyone a title, after claiming they would if it ever turned up?

So this title validated a body shell, with a couple wiper holes and one wire routed to a taillight, as a registered road-going car up until 1981. This document also revealed the here-to-fore unknown Snedeker Special, no doubt penned for the original builder. Tracing the title address to a prior owner in Oklahoma presented a rather hostile guy whom only offered that he thought it was a Henry J chassis with 289 Ford power, but he also made it clear that he didn’t want me to contact him again.

Not a complete surprise if you’ve ever done much automotive archeology. My spirits were dampened to the point that I dropped the chase for a couple years. Then I thought, why not do an Oklahoma title search? It was only a matter of a form, a nominal fee and a couple weeks cooling my heels before I had the envelope in my hand. “M. A. Reed of Wichita, Kansas,” I read with disappointment. I’ll never locate anybody with a name like that.

Sure enough, no hope of finding somebody with a common last name and no first or middle name, however I was able to Google the address and look at the puny suburban house with its attached one-car garage and imagine the Snedeker SR100 lurking there during its wonder years. Motivation again lagged for a couple years until it occurred to me that this Snedeker guy might still be out there. His uncommon Dutch name was shared by a famous golfer, so Google only led to too much about golf and nothing about SR100s.

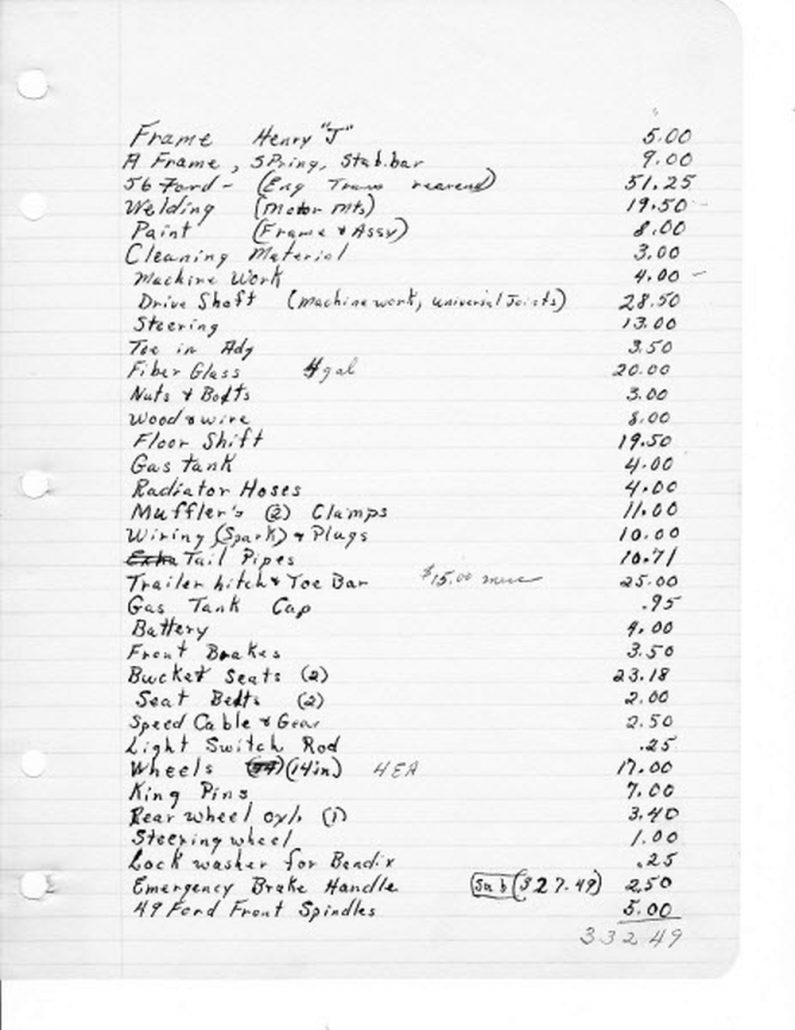

So let’s see, the Oklahoma title search led to a Kansas address, but not Snedeker. How about a Kansas title search? Once again a form and a small fee rewarded me with a fat envelope in my hand. It contained multiple title copies from former owners and the crown jewel, the original title application from Leo Snedeker of Wichita. I suspect a single piece of DMV paper has never been more descriptive of a car build. It stated that the chassis was a Henry J. sourced from Ace Salvage Co., the motor was a Ford, and the body was a “K-Byers.”

Clearly the second star aligned for me at this point.

Next I found Leo’s daughter, Leticia (Tish), through the internet and we talked on the phone. Sure enough, Leo was 79 and still full of life and in fact traveling at the time. She said she was very young when he built the car, but remembers the smell of the fiberglass. Before long I had email contact with Leo and he sent me some original photos and scans of build sheets which detailed every part, service and cost.

Three stars now aligned and I anxiously sent a photo and word to our guru, Geoff Hacker. Before long my phone was ringing – it was Geoff. “You need to get with Leo and put that car back together correctly.” “But, I want people to respect the Byers,” I said. “I want it to perform with a modern chassis and powerplant.” “You won’t get respect,” Geoff replied. “You’ll be explaining to everybody what kind of weird kit Cobra you have and will squander the lineage you put so much energy into finding.”

Well, as Geoff informed me, nobody has found a car builder through a title search before and Leo may be the last living Byers builder to reunite with his car and effect a proper restoration. Basically Geoff was telling me all the stars had aligned for me and I would be a fool to misalign them. It didn’t take me long to get on board. This was the same standard I had espoused in vintage racing so why go down the wrong road?

Within weeks I was on my way to visit Leo in rural Kansas with a Henry J. chassis in tow. I was greeted by Leo and Tish as I pulled into the quaint homestead, tucked in between corn fields along the buzzing highway that hinted at Wichita’s encroaching sprawl. They were very cordial, but there was still an awkward curiosity in the air that begged me to explain why I would travel over 500 miles to greet complete strangers with a rusty 1950’s chassis and some body parts.

I stiffly started to recite Geoff’s dissertation of American post-war, hand-built sports cars. When I got to the part about the 2000 hour investment that it took to build a car, Leo interjected, “I don’t think it took 2000 hours.” “How long did it take?” I asked. “Every waking moment,” replied Leo stone-faced, which pretty much said it all. In suburban driveways and rural outposts all over the country, can-do guys were defining a new era of automotive ingenuity.

This seems like a good time to tie in the human condition as it relates to the hobby. “Projectitis,” I call it, refers to stalled or stillborn projects, but could also apply to the constant yearning for a project, as many of us do, even to our own demise or the demise of current projects. I suspect you could overlay trends in projectitis and they would correlate closely with other elements of human behavior.

For me, I judge myself harshly if I feel like I’m stalling, like I’ve let something defeat me or failed to muster enough self-discipline to finish a car. So, I embrace the mantra of “inching forward.” It’s just like working out, if you stop, the odds are you’re not going to pick it up again or will have to start over from scratch. If you keep a continuum of minimal activity going, you never completely void the relationship with a project.

I’ve had this project, among several others, for seven years now. I have spent much time measuring, looking, thinking, buying parts and occasionally patching small areas of fiberglass. Just looking or cleaning is considered a valid part of “inching forward” because it keeps the project alive in your head, not buried under a kiddie pool and inches of dust in your garage or worse yet, rotting in the back forty. Research too is considered “inching forward.” Now, consider a kick in the pants like finding the original creator of your car.

I don’t think Leo Snedeker ever suffered from projectitis. We stand in the shadows of the house he built flanked by a shimmering blue pond spouting a scenic geyser, along with various outbuildings – all Leo projects. He built the SR100 in his cramped suburban driveway before moving to the country, not a shop or garage like my pampered generation.

Shortly after the car was completed, Leo, already an Air Force Staff Sergeant, shipped out to Thailand to serve in the Viet Nam war. He bartered the car to a local guy who built fiberglass dirt racers for incentives and materials to build another car when he returned from the war. “I knew I would build another one,” Leo stated matter-of-factly.

Let’s talk about the build. Where did Leo get the idea for an SR100 to begin with? Believe it or not, J.C. Whitney, that intriguing bathroom reference loaded with gadgets and upgrades for just about any vehicle. I don’t think we’ve heard of this source before as a means of acquiring a Kellison-Byers body. Leo’s build sheet shows he paid $295 for the body and $58.19 in freight to have the huge crate appear in his driveway.

He said the body was supposed to have hood and door stiffeners, but after calling the company these lacking items were explained away. Curiously, Leo also said that his short hood/scoop configuration arrived that way and had a baffle plate in the opening of the scoop to deflect water.

Remember the bygone days of freely roaming salvage yards for parts and entertainment? Well, Leo was the denizen of the junkyard. Once he had an idea and a few measurements, he was off to Ace Salvage or other outlets to size up a donor. Take for example the windshield, we know the Byers was designed for an early ‘Vette variant.

No doubt a prohibitive prospect in those days as they are today, many builders opted for other solutions. Leo told me that he measured it out, thought about it and then hack-sawed the windshield out of an unknown salvage sedan that met the specs. He said adapting it to the SR100 and smoothing it out was a colossal amount of work. You can see the product turned out well (below) and can understand how quickly 2000 hours would add up.

Leo likes to tell the story of the highway patrolman who came by his house to inspect the car for a title and license plates. At the time the SR100 was no more than a Henry J chassis and a plywood floorboard. “Where’s your windshield wipers?” asked the patrolman. Leo replied that they obviously weren’t there because the body had not arrived yet. Satisfied with the explanation, the officer issued a set of plates.

As we get into the nuts and bolts of the build, we learn that much of the working gear was sourced from a 1956 Ford station wagon. Typical of even today’s kit cars, donor cars were available because they were old enough to be wrecked or used up. Hence the 292 Y-block power when the new 260/289 Windsor small block had relegated the Y-block to retirement.

This adds more powerplant diversity to Byers history as we’ve had early Chevys, a Buick Nailhead, DeSoto Hemi, a VW, a Triumph four and now a Ford Y-block, among others I’m sure I’ve left off. Though out of production at the time, the Y-block was no scrub. Having been the motivation for 1955-57 Thunderbirds, plenty of performance goodies were available.

Leo opted for many transplants from the Ford donor, including the steering column, pedal assembly and entire rearend housing, all of which took time to remove from the lifeless hulk. Likewise with the Henry J chassis, it was not just a matter of dragging it home from the salvage yard. Leo had to strip the entire body and accessories from the frame before it was free to go. More hours were ticking away.

The Henry J, named for Henry J. Kaiser, was a popular foundation for early fiberglass sports cars as the 100” wheelbase offered a direct bolt-in chassis in the days of behemoth donors that required shortening. Even Byers literature had instructions on how to shorten a Ford frame by 14 inches. However, there appears to be some disdain for the Henry J chassis in restorations. Several have been completely scrapped in recent years in favor of modern platforms. After examining a Henry J skeleton up close, I’m a little baffled by this trend.

It very closely resembles the 1953 Corvette frame that debuted a couple years later, even down to the A-arms angled back from perpendicular. The Henry J frame is factory boxed and skip-welded (below left), which is something guys spend lots of time doing after-the-fact.

The Corvette still used open C-channels, which required the center X-bracing typical of older designs. Skip-welding is a common practice in reinforcing racing platforms. Also note the Henry J corner gusseting, similar to racing reinforcement (below right).

The modern Henry J following mostly centers around vintage “gasser” drag cars and those guys praise the strength of the unmodified Henry J chassis under the stress of mega-horsepower engines. For 1949 technology, I expected something much more primitive. You have your basic rear leaf spring arrangement, which Leo tells me will take a Ford rearend, bolt-in.

A drawback that Geoff pointed out was the Henry’s narrow track that made some cars look top-heavy on yesteryear’s skinny tires. So, in today’s big tire world, why would that be a negative? Even on skinny tires, Leo can’t explain why his track width seemed to come out right, other than the Ford rearend and possibly the transplanted 1949 Ford front spindles. Bottom line, the Henry J platform is sturdy and adaptable to modern handling upgrades.

As such, Leo told me not to use the Henry J leaf springs because they were too weak. He field tested them after bowling with his wife one night in Wichita. At a red light somebody pulled up next to them. “I think he wanted to race me,” declared Leo. Not a man of indecision, Leo hammered it and the rearend twisted on the weak springs and broke the foot-long driveshaft.

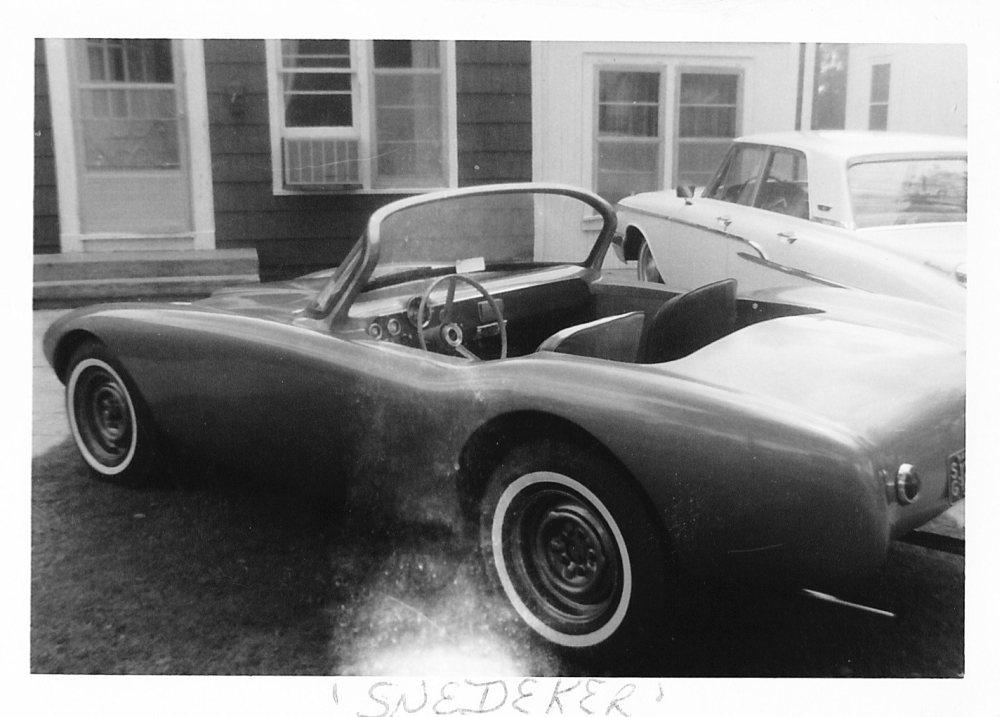

The Byers SR100 body has a very low belt-line. If you sit on top of the frame, you jut out of the car like a Shriner in a go-kart and peer right into the windshield frame. The only solution is to get the seats down in between the frame rails, but the narrow Henry J doesn’t allow for two posteriors and a driveshaft in such tight quarters. Leo first tried to remedy this by “boxing out” an inner section of the frame – still not enough room. So much for the ease of a bolt-in chassis.

Leo had to defer to a welder and have an entire section cut out of the frame and boxed outward to make the seats drop down in. Here he points out how this needs to be done (below). This modification and the repetitive on-and-off fitting of the body to the floorboards was very time consuming. More hours ticking away in a Wichita drive-way.

Kit cars offered flexibility for the builder to create his own vision with any combination of parts at his disposal. Such a vision tastefully carried out to completion reinforces the importance of these cars today. Done right, you could capitalize on hybrid vigor. That would be spawning a handsome child from ugly parents. Not only was the 1965 Snedeker a huge undertaking that had to be immune from projectitis, but the end result was different from any other SR100 constructed in an American driveway.

We know cars weren’t always completed, but the real surprise in this story was the level of completion and refinement in the Snedeker Special. Leo’s build sheets show that he purchased dye to match the carpet color to the interior. He used a 55 Buick speedometer, Stewart Warner Greenline gauges, an ash tray and Corvair radio to make the dash fully functional (below). Volkswagon wipers serviced the windshield, while a custom tonneau cover allowed driving from a small cockpit opening or complete closure when parked.

After a busy day talking, looking, scanning pictures and photographing more, we settled down to good old country meal whipped up by Leo’s wife, Lorraine, while the local news blathered away in the background. Conversations reverted back to the weather and the news of the day, all requisites of a seemingly typical, humble American home, not the place you would expect to germinate an exquisite American sports car.

It told of an era when you could build your own personna in a shape much better than your’s, thanks the wonderful medium of fiberglass and companies who could make a large crate appear in your driveway for a nominal fee. Add a couple junk sedans, various, salvage organ transplants and climb aboard. Oh, don’t forget the 2000 hours of labor or working every waking moment, whichever came first.

Of course the story of the restoration goes on, but there is also one more wrinkle to figure out. When Leo turned the Snedeker over to Mr. Lynn Long and left for the war, the car was stripped and had all it’s orifices glassed over. This included taillights, hood scoop opening and side fuel filler for the Henry J gas tank. In our first story we were mystified by all these changes and just assumed somebody remodeled the car to their taste.

It wasn’t until we found Leo that we learned all this was done to pull a mold off the car. Either Mr. Long, or the subsequent two Reed family members that owned the car, reassembled it with a new one-off fiberglass dash and Cobra’esque features like an Eelco racing fuel flip-cap and outboard taillights. Additionally they changed the color to a loud orange hue.

It was a surprise when Leo said he had painted the car a deep blue because there were only two eraser-size specs of blue left on the car. Well, I need to quit stalling and start knocking down my 2000 hours, that great chronological credit to builders that may also be the nemesis to many a restorer. Forget the 2000 hours, just set aside every waking moment until you’re done.

Summary:

What a great story on a car and the man who built it – Leo Snedeker. As Dave noted in his story, this is the first time that a title search resulted in complete enough information to help in locating the original owner/builder of a car. I admire the tenacity shown by Dave in hunting down this critical information! And what a great story he was rewarded with – one that I’m grateful that he shared here with us at Forgotten Fiberglass.

And what Dave is doing is breathing the soul back into the car and its history. By working with the original owner/builder and bringing using his guidance to recreate the missing chassis and drivetrain – exactly as it was in the original build – he is saving a piece of history and documenting the process of the build for future generations to appreciate in the greatest detail. Thanks for doing this Dave – a service to the cars we admire and respect for the men who designed and built them.

But wait gang…..there’s more!

Did Dave mention to you that he found a second car built by Leo Snedeker – one that was driven for many years and has over 30,000 miles on it to boot! More about that in a future article so stay tuned gang 🙂

Hope you enjoyed the story, and remember gang…

The adventure continues here at Forgotten Fiberglass.

Geoff

I have known Leo since high school years in the 1950’s and embarrassed to say I did not know this about him! I knew him as a special friend and my brothers friend! You are so gifted Leo! Very proud of you and all your talent!!

Excellent story, looking forward to more updates – I can’t wait to see what it looks like when it is finished. Thank you for sharing this Geoffrey!

Great research and story Dave.

Several times, as I read your story, I thought I was reading notes from my own research… Chasing common names, trying to find “mystery” people, places, etc. and of course having a few conversations with Geoff about how best to build the car so that it reflects the vision, design and intent of the original builder vs. “modernization” of it. I’m glad that you are following Geoffs’ suggestion and putting the history back into your car. Can’t wait to see it done and one the road.

I would also love to get photos from you and Jean Poirier on how your Henry J frames are setup, and how the bodies are mounted My Cougar was never finished and has a “new” (never used) Henry J under it. I must fabricate everything to mount the body so seeing photos of other setups would be helpful in planning my build.

Thanks.

Darren

Thanks Boys for the kind and helpful words. I’m glad to know you share my challenges and fun. I will no doubt be contacting some of you for advice. I for sure would like to see a bare Henry J with a V-8 mounted in it to see how much room is left for foot-wells before the frame is boxed out. Take care all,

Dave

Great job Dave , My Glasspar uses the same Henry J frame, I zeed my frame and added outriggers for body support, now you can sit in it like a go-kart. If I can help with any pictures or measurements contact me through Geoff.

Awesome love to hear these stories. I need all the inspiration I can get to make me go out and work on my Projectitis. God speed!

Javier

Great story great photos.

Looking forward to seeing the finished car in full living color.

Mel

What a great story. I have always thought that the SR-100 has better lines than the 289 Cobra.

Really enjoyed the article. It is right on as to the number of hours involved in building a car. Both physical and mental hours involved.